Tig welding is an excellent method to create awesome metal workpieces. However, if you have done some research on it, you will find that tig welding is easy as pie. That’s why we’re here to provide you with a list of advice on how to setup tig welder!

When you get the hang of tig welding, this challenging task will become your best friend accompanying every workpiece. So stay tuned and scroll to the end of the following article to receive the easy-to-follow guide on setting tig welder right now!

Table of Contents

Guide On How To Setup Tig Welder?

What is tig welding?

Before breaking down the details of setting up tig welder, let’s find out some necessary information about tig welder first so that you can have enough adequate knowledge of tig welder to work effectively with it.

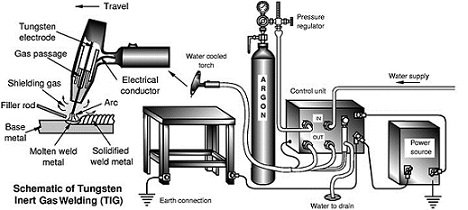

Tig welder is a tool used to make welds or curves on various types of metals and keep them connected for a long time. How can it manage to do this? It’s because when reaching a certain high melting point, tig welder should create a non-consumable electrode, which doesn’t melt.

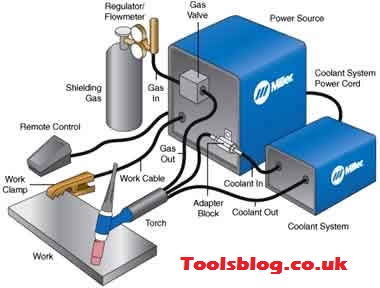

Here are significant components of a tig welder that you need to know:

- Electrode: it’s a long and slim metal stick, which is crucial in the welding process as it helps channel the current to join metals.

- Collet: collet is a short piece of copper covering a part of the electrode and keeping the wire remaining in its position.

- Endcap: By adjusting, loosening or tightening the end cap, you can easily adjust the length of the electrode so that it perfectly fits your scale of work.

Necessary steps to set up tig welder

After finding out what tig welder is, now we will continue to provide you with some guided setting up steps:

Step 1: Select a suitable electrode

As mentioned above, the electrode is the most crucial part of tig welder; that’s why you need to be careful when choosing one. Different metals and scales of work require different types of electrodes, so consult your experienced friends or official sources of information to pick the most suited electrode!

Step 2: Grind the electrode.

To create high-quality curves and welds, the electrode needs to be pointed or rounded, in particular, if it is a new one.

Step 3: Attach the electrode to the collet

Unscrew the electrode holder, insert the rod, and then screw it back. So easy, right?

We recommend that you should leave the tip of the electrode about ¼” maximum away from the sheath.

Some tig welders have this part available before your purchase, so check whether you have to take this step or you can skip it.

Step 4: Recheck your tig welder.

The assembly work is almost done! However, before welding, make sure that all parts are correctly assembled and attached in order to avoid any unnecessary accidents or hurt yourself.

Step 5: Weld!

Now your tig welder is ready for any work! Don’t forget to put on safety clothes and wear glasses. Safety is of our utmost priority, so you should take all needed protective measures, and get started to weld.

Remember to remove any remaining clamps, then be careful with every movement of the tig welder and regulate the current according to the condition of metals.

We are sure that you will be impressed by the beautiful curves made by yourself!

Final Thought

Now that you have gained all necessary information about tig welding and know precisely how to setup tig welder. Technical pieces of stuff are sure to cause you some trouble and throbbing headaches whenever you have to work with them. And that’s also the case of tig welders.

However, if you spend a little amount of time and effort to gain an in-depth insight into this challenging task, tig welding is no longer complicated! So who wants beautiful metal pieces? Let’s follow our guide as above and work effectively on your own!

Leave a Reply