How Does An Impact Wrench Work?

An impact wrench is a useful tool that assists you in removing or tightening nuts and bolts; both air and electricity power it. This tool is favoured by people who love DIY projects thanks to its effectiveness and usefulness that can help you with many purposes.

Yet, how does an impact wrench work?” If you are interested in using this tool and curious about the way its functions, you’ve come to the right place! Scroll down now!

Table of Contents

Parts Of An Impact Wrench

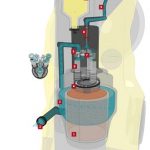

Various parts make up an air impact wrench can be seen when dismantled:

- Rotary cylinder: It is a part wherein the compressed air can enter via its two ports: intake and exhaust ports. You could find these two ports at the cylinder’s bottom. Inside, the rotary cylinder contains the blades and wheel, spinning when the compressed air enters or exits.

- Rotational wheel: It converts compressed air into rotational energy and allows this energy to move from the wheel to the tool’s impact system.

- Rotor blades: They are connected with the rotary wheel via different slots on it. Compressed air moving between these blades will be transferred into kinetic energy.

- Rear and front rotary endplates: They ensure the rotary blades and rotary stay in their place during the process.

- Hammer cam: It can transfer energy from the compressed air into the impulse force.

- The hammer dog: This part ensures locking and releasing one impulse per each tool’s revolution. It’s held in a place by an anvil and located in the hammer cage’s inside.

- Hammer pin: It will ensure the hammer is held in the external cage.

- Anvil: It is a part wherein the various torque extensions and sized sockets connect.

- Directional valve: It controls the compressed air flow’s direction into a rotator cylinder. Beyond that, the valve will enable the user to influence the wheel spins’ direction clockwise or anti-clockwise.

How Does An Impact Wrench Work?

Compressed-Air Impact Wrench

Compressed-Air Impact Wrench

The compressed-air version works by applying torque or rotating energy to fire it in a short burst. Specifically, the high-pressure air powers the torque of rotating energy, making the impact wrench run seamlessly.

Stage 1: Air Goes Into The Rotor Blade To Make It Spin

It requires a constant air supply to operate properly. The adapter powers the airflow via a hole, and the controller will decide which holes the air will pass through.

However, there are two holes in the wrench’s inside base. The pressurised air enters the device’s system through one or two holes and exits at the backplate.

Stage 2: Make Rotor Cylinder Spin To Create Energy

Another component of this rotor cylinder is the rotor spline, connecting to the hammer to create the mass and applying the high force on a bolt nut.

Stage 3: Deliver Energy To The Handle To Do The Work

Another hammer’s part, known as the handle, moves back and forth when the trigger is pressed. This process creates a mass to accelerate at high speeds while rotating or screwing into place on lug bolts or nuts.

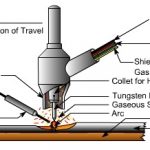

Electric Impact Wrench

Electronic impact drivers (both cordless and corded) seem to operate as the air-compressed ones, yet they use the electric motor as the power source.

Both cordless and corded types have their own impact functions. An impact function produces powerful rotating bursts of force, transmitted to the drill bit to screw in bolts and nuts.

Stage 1: Activate the Impact function

The impact function – created by a hammer and anvil mechanism, will activate when the output shaft or the anvil contact resistance.

Stage 2: Create Burst

When the tool triggers, the hammer disengages from the engagement pin and revolves in a circular motion at a fast speed.

As it gathers more energy and speed by abruptly forcing it back into contact with the anvil, the stored energy in the brief burst will release.

Stage 3: Deliver Energy To The Work

You could complete your task thanks to the process of delivering shorter bursts (about 5 seconds). This motion drives the stubborn lug nuts.

If resistance is detected again, the process will be repeated.

Understanding how the impact wrench works is vital.

Our Final Thoughts

Now, you know everything about how an impact wrench works! As we’ve listed above, there are two types of impact wrenches: compressed-air and electric. Each type of them has different functions, as well as disadvantages & advantages. Hopefully, you can use both types effectively after understanding how they work.

Leave a Reply