An impact driver is a large-sized power tool that spins at high speeds to drive screws into wood, metal, or masonry. This blog post will cover how to use an impact driver for the most effective results. We’ll also go through details of how to use two types of this machine and suggestions on when to use the impact driver. Read on!

Table of Contents

How To Use An Impact Driver?

There are two main types of impact drivers you should pay attention to:

Manual Impact Driver

Manual impact driver

A manual impact driver can be quite confusing to use at first, but we’re here to help. We’ll teach you what this tool is all about and how it works in a simple way so that you will never get confused again!

Step 1: Safety And Preparation

First and foremost, you must ensure that all the essential arrangements and tools are ready. To get started, keep in mind several things as follows:

- Protect your eyes from debris by wearing your safety glasses.

- Protect your hands with a pair of rubber gloves while conducting heavy-duty work. The thicker, the better. In this way, you could minimise the injuries caused by hitting your hand with your hammer.

- Lastly, force fastening the screws/bolts with the hammer.

Prepare the tool after completing all the steps above; make sure you have the proper size and shape before attaching it to the driver. To put in a new bit, lift the chuck upwards, insert the selected bit, and then lower the chuck again. Afterwards, check the bit again to make sure it is correctly put in.

Step 2: Position The Tool Properly

Hold the impact driver with your non-dominant hand. Fit it on the screw’s top and make them come out of the surface. This tool is easy to use, as there are no buttons or clutches that need pushing.

Also, like a regular screwdriver, it’s vital to make sure all the bits fit in tightly and are held straight.

Step 3: Strike the Manual Impact Driver

With a bit and screw top that seems like they’re fit with each other, use your free hand to strike an impact drill with the hammer.

At the same time, rotate your impact driver to tighten or loosen screws based on your purpose. You can rotate clockwise for tightening and counter-clockwise for loosening.

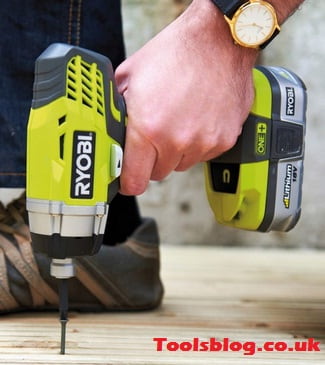

Electronic Impact Driver

Electric impact driver

Step 1: Safety

Safety is the leading criterion. Though this machine is not as dangerous as a table saw or chainsaw, it may cause several minor injuries.

When working on the impact driver, we recommend you wear a mask. It will prevent you from breathing in particles that may irritate asthma and other respiratory conditions.

Some safety goggles can also protect your eyes, as debris could fly out accidentally when the tool strikes metal or wood materials during fastening applications. Finally, a pair of gloves is needed to prevent cuts in the event of slipping.

Step 2: Put The Battery In

With a fully charged battery attached, slide your impact driver into place. The magnetic bit holder will suck the screw in and keep it from falling out as you drive!

Remember to switch the impact driver off before inserting the battery. Simply slide it into its handle to insert the battery until you hear a ‘’click’’ sound inside.

Step 3: Choose and Insert The Bit

To choose the correct bit for your impact driver, you had better observe the screw’s head and understand the screw’s shape.

After you’ve matched the screw head to the bit:

- Find the length you want to use an insert in the chuck.

- Use one hand gripping the chuck and pulling it upwards to attach the bit into the chuck.

- Use your other hand to insert the bit.

Step 4: Run the Impact Driver

Once you have securely attached the bit to the chuck, adjust the forward and reverse switch to fit the purpose of using your impact driver. Then, select an appropriate speed for your impact driver.

Now, slowly press the button/trigger at the front of the impact driver to rotate your chuck and bite in the set direction. Lower or increase the rotation’s speed according to what you’re working on.

Killing the drill in place requires certain adequate pressure. Yet, you could use an impact driver for drilling easily with the help of just wrist movement without putting in too much strength.

Step 5: Complete

Before removing its battery and the bit, let this tool cool off for a few minutes by setting it aside on a flat surface. Otherwise, the heat produced during rotation might cause injuries without proper cooling.

When Should You Use An Impact Driver?

You can benefit much from using such a high-end impact driver

You can use the impact driver in many cases and projects, such as:

- Building: Log cabins, Sheds, Loft, etc

- Shelving

- Decking

- Furniture Assembly

- Roofing & Flooring Jobs

- Minor jobs: repairing and fitting home accessories and appliances

- Fencing

However, avoid using the impact driver in projects where the hole’s size or replacement is less important than the required torque. Impact drivers are also unsuitable for drilling into some hard materials like concrete and brick.

Our Final Thoughts

Impact drivers are a great way to make your projects and woodworking tasks easier. They do this by driving screws with an impact driver, which is quicker than using a manual screwdriver or drill.

You’ve known how to use an impact driver effectively and safely. Yet, we recommend practising with one at home before you start any construction project.

Leave a Reply